General e Project Cargo

GENERAL CARGO

The “General Cargo” includes all goods whose load requires one unit (housing/seat) to be transported.

These kind of goods are usually packed or contained (linked one to each other, arranged in a certain order); examples of general cargos are : packages, pallets, cartons, rolls, logs, etc.. Their handling cannot usually be done with pumps or fully automated systems, but with cranes operated by the staff of the hold and the quay.

PROJECT CARGO

What distinguishes the “Project Cargo” is essentially the destination of the goods: the place of arrival is the site of construction of a plant, an oil well, etc..

From this it follows that the Project Cargo has different transport requirement, with voluminous and heavy materials, including components of industrial equipment that cannot be shipped as a single unit load. In addition to the type of goods there is also a more complete organizational component (expediting, pre-shipping, forwarding, material management) and a compliance with more rigid quality standards.

Harmonized System (HS) Code and TARIC code

HS CODE

The movement of goods between the different states is distinguished by a classification system that provides the assignment of a code to every type of goods. The Harmonized System (HS) is the international standard for the classification of every type of goods.

This system is managed by the World Organization WCO (World Customs Organization). This numbering system is used in trade between the nations, both in exports and in imports, in order to allow a clear and rapid identification of the handled goods and is currently being used by more than 200 countries around the world and covers more than 98% of goods that are traded internationally.

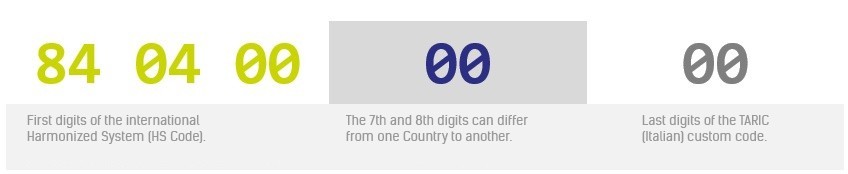

The entire classification is composed of 21 sections and 99 chapters. The Combined Nomenclature includes thousands of items; there is a numeric code of eight digits that correspond to each product. The first six indicate the nomenclature items and sub-items of the Harmonized System of Classification of the goods, while the seventh and eighth digits identify the combined nomenclature sub-items (NC); to these last ones are added two additional digits that indicate the sub-items of the Customs Tariff (TARIC) that determine the rates of customs duties for the goods in import, according to the origin of goods and various measures of trade policy.

TARIC CODE

The TARIC code is a method for classification and identification of goods of the international trade between the Member States of the European Community with the aim of determining the custom tariffs. The correct coding of goods is extremely important because it affects the application of import duties.

Example of TARIC code:

The entire classification is available on the website: www.adm.gov.it. which also contains the explanatory notes, information concerning prohibitions, licenses, indications of the required certification for the application of preferential rates, the reference to EU laws and many other information related to the export and import of goods.

Classification of dangerous goods

The transport of dangerous goods by road, rail, sea, air is subject to specific international regulations that impose special operational requirements:

- DR Agreement (for road transport click here or more information)

- The IMDG Code (for sea transport, click here for more information)

- IATA DGR code (for air transport, click here for more information)

- The RID (rail transport, click here for more information).

These regulations require that all the operators involved in a shipment of dangerous goods must meet the mandatory requirements for the proper management of the choice of the appropriate packaging, labeling, issuing of shipping documents (DDT, Multimodal Dangerous Goods Form, Shipper’s Declaration) and control of the means of transport.

Each person involved in the transfer of dangerous goods (sender, shipper, carrier, consignee) has its own specific duties. For example, the sender must deal with the classification of goods, the choice of appropriate packaging (containers or tanks) based on the hazardous characteristics of the goods and provide the carrier with the necessary documents in order to arrange the transport in the best possible way and security.

CODES OF DANGEROUS GOODS

The codes of dangerous goods consist of 1 to 3 digits, which indicate respectively the main (1), the secondary (2) and the tertiary (3) type of hazard according to the type of material. The code is supplemented by other four digits which indicate the specific code of the material, defined as number UN, to which corresponds the transported goods uniquely around the world.

Below is the table of the primary dangers:

NUMBERS

AS 1ST NUMBER

AS 2ND AND 3RD NUMBER

0

No specification

1

Explosive

2

Gas

Gas emanation

3

Inflammable liquid

Inflammable

4

Inflammable solid

5

Combustive agent

Combustive

6

Toxic

Toxicity

7

Radioactive

8

Corrosive

Corrosiveness

9

Danger of spontaneous violent reaction

Danger of spontaneous violent reaction caused by a spontaneous decomposition or polymerization

LABELS OF DANGEROUS GOODS

The labels are the graphic representation of the dangerousness of the material, the more easily identifiable than a series of numbers. To a certain type of goods may be associated with different hazard labels.

Classification of dangerous goods

TEMPERATURE CONDITIONS

- REFRIGERATED PRODUCTS, 0° C / 2° C – 85% humidity – the meat of slaughter animals (cattle, sheep, pigs) are kept good for about 30 days under optimal conditions, while poultry is kept for 6-7 days if without entrails; in addition, this technique is adopted in the transport of fruit and vegetables (higher temperatures +2°/+4° C).

- FROZEN PRODUCTS, products that are kept at low or very low temperatures (-15 ° C / -20 ° C) therefore the water (which represents approximately 70% -80% of every food of animal and / or vegetable origin) crystallizes and the product solidifies.

- DEEP FROZEN PRODUCTS, this is the same technique as per above mentioned with the difference that the cooling and consequent solidification of the product must take place in a very short time (within 4 hours) with temperature not exceeding -18° C.

The frozen products and / or deep frozen cannot in any way abandon the “cold chain”, while as regards refrigerated foods, these ones cannot be subjected, during transport, to big oscillations of the optimal temperature maintenance. The temperature conditions that must be respected during transport are indicated in the documentation required for shipments by road, sea, air and rail.

The transport of such products is almost exclusively arranged by trucks with mechanical refrigeration and independent cooling equipment in respect to the truck . This system offers the best guarantee of security, especially for international transport, during which the “cold chain” must be kept active for several hours.

CERTIFICAZIONI